A hydrogen-cooled superconducting cable offers the possibility to distribute in the same infrastructure both a large quantity of hydrogen and electricity in the gigawatt range. These two energetic vectors are key to supporting the decarbonisation processes in Europe. The work will include the integration of safety requirements both into the design and the operation of the cable system. As a final validation, a long-term testing program will be carried out to demonstrate the reliability and maturity of the proposed solution.

Key activities

The work package is supported by two main pillars:

1. Design of the cable system

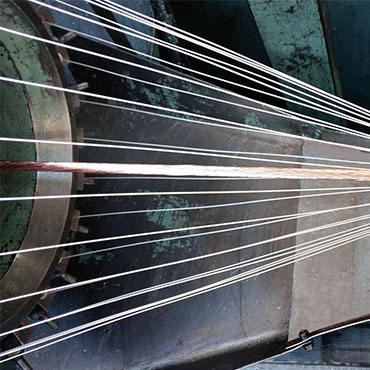

During the first half of the project, the conceptual and technical design of a complete set of components for the hybrid cable system will be carried out. This includes the latest developments on MgB2 wires and cables, terminations and field joints, cryogenic envelopes, hydrogen liquefaction with its associated cooling system. Scientific modelling will be used to validate transient phenomena such as fault currents and ripples. The designs will take into consideration the safety requirements for operation in hydrogen and will also be easily adaptable to other requirements by the end users such as different operation currents or voltages.

2. Testing of the cable system

The concept of the hybrid cable will be demonstrated by the manufacturing, assembling and testing of a full-scale cable system with the following specifications:

| Characteristics | |

| Design | DC monopole |

| Power transmitted | 500 MW |

| Current transmitted | 20 kA |

| Voltage | 25 kV class |

| H2 flow | up to 10 kg/h |

| Overall diameter | 60 mm |

| MgB2 cable diameter | < 25 mm |

The second half of the project is devoted to the testing of the cable system on a dedicated platform (type test procedure) followed by long-term field testing to prove its reliability. As no standard is available today for DC superconducting cables, adequate testing sequences will be proposed, studied and implemented during the demonstration phases.